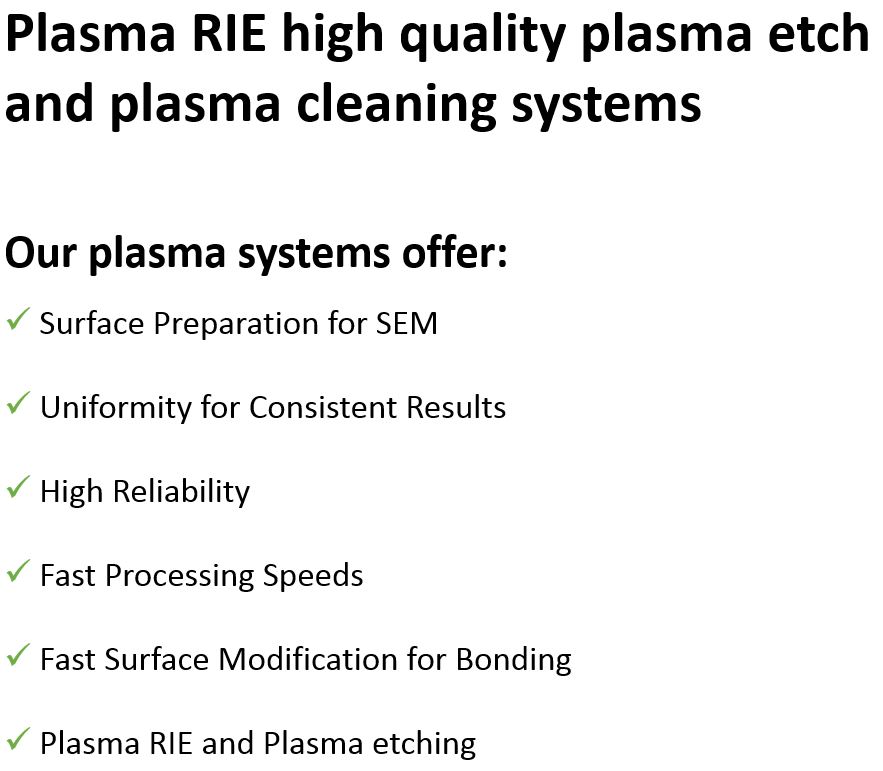

Ekrub Nano is your Plasma etch FA Sample prep Solution

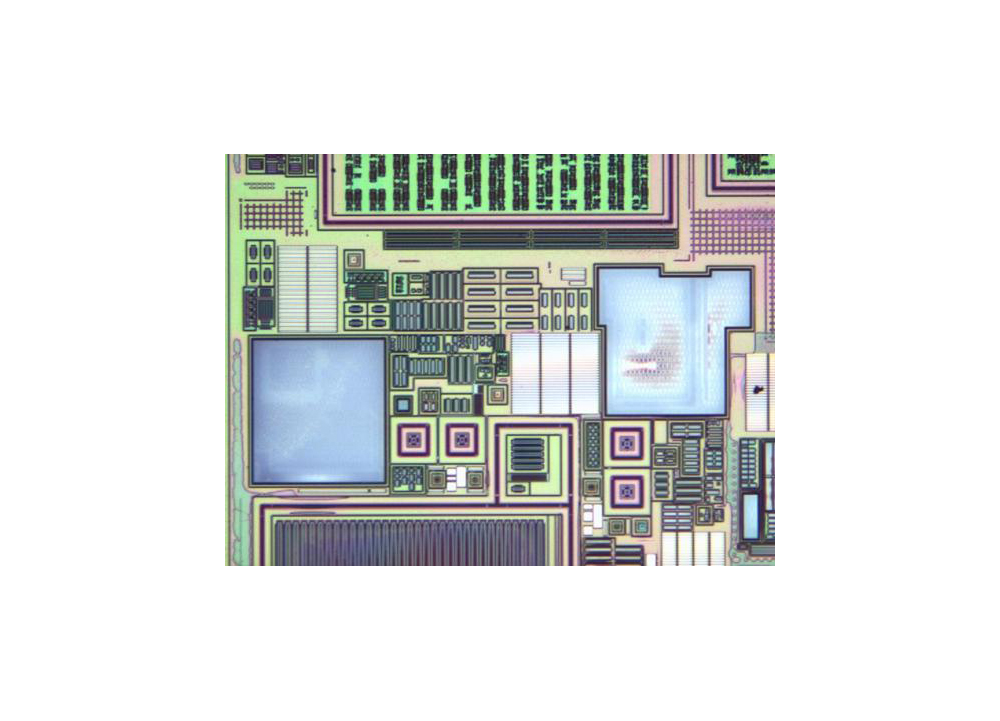

Die delayering techniques exist, e.g., plasma etching, reactive ion etching.., etc. A typical die delayering sequence starts with either plasma or reactive ion etching to remove the nitride passivation on top of the die surface,

Plasma etching is a dry and anisotropic etching process that consists of the following steps: 1) a plasma discharge produces chemically reactive species from a relatively inert gas; 2) the species diffuse to and get adsorbed by the surface to be etched; 3) the species reacts with the surface, producing a volatile byproduct; 4) the byproduct is desorbed from the surface, completing the etch process; and 5) the byproduct is released to the bulk gas.

Reactive ion etching is similar to plasma etching, except that it involves bombardment of the surface being etched with accelerated reactive ions. These accelerated ions sputter material off the substrate as they hit its surface, as well as react with the substrate material. Thus, with RIE, etching is accomplished by two processes: sputtering and chemical reaction.